OEM Best Lts Check Valve Supplier – API 602 Forged Check Valve – Guangwo Valve

OEM Best Lts Check Valve Supplier – API 602 Forged Check Valve – Guangwo Valve Detail:

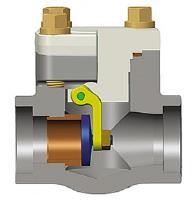

Forged steel swing check valve

Forged steel check valve is to rely on the flow of the medium itself and automatically open and close the valve disc, used to prevent the reverse flow of medium, also known as check valve, one-way valve, reverse flow valve, and back pressure valve. Check valve is a kind of automatic valve. Its main function is to prevent the reverse flow of medium, reverse rotation of pump and drive motor, and discharge of container medium. The check valve can also be used to supply the auxiliary system in which the pressure may rise above the system pressure. Check valve can be divided into swing check valve (rotating according to the center of gravity) and lifting check valve (moving along the axis).

Forged steel swing check valve-Features

1. The body is forged steel and available in reduced and full bore design

2. Bolted bonnet Welded Bonnet or Pressure Seal Bonnet

3. Swing Type, Anti-Rotation Disc

4. Renewable seat rings

Forged steel swing check valve- Specifications and standards

1. Design standard: API602, ASME 16.34

2. Pressure temperature standard conform to ASME 16.34

3. Face to face dimension conform to CGV standard

4. Testing and inspection standard conform to API 598

5. Flanged Ends to ASME B16.5

6. Butt Welded Ends to ASME B16.25

7. Screwed Ends to ASME B1.20.1

8. Socket Welded Ends to ASME B16.11

9. Ends Flanged ends, Socket Weld End, Screwed End, Butt-weld end

10. Size range:1/2’’~3’’(DN15~DN80)

11. Class :150LB, 300LB,600LB,900LB,1500LB,2500LB,4500LB

12. Body material:ASTM A105, ASTM A350 LF2, ASTM A182 F5, ASTM A182 F22, ASTM A182 F304, ASTM A182 F304L, ASTM A182 F316, ASTM A182 F316L, ASTM A182 F347, ASTM A182 F321, ASTM A182 F51, ASTM A182 F55, Inconel Alloy, Monel Alloy, Hastelloy Alloy.

13. Trim material:F6a / F316 / F304 / F316L / F321 /F51 / F55 / Inconel / Stellied or Hardfaced

Product detail pictures:

Related Product Guide:

With our loaded practical experience and thoughtful solutions, we now have been identified for a trusted provider for numerous intercontinental consumers for OEM Best Lts Check Valve Supplier – API 602 Forged Check Valve – Guangwo Valve , The product will supply to all over the world, such as: Birmingham, Jordan, Sri Lanka, When It produced, it making use of the world's major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a "people-oriented, meticulous manufacturing, brainstorm, make brilliant" company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we will be delighted to serve you.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.